Tue August 17, 2021

Metso Outotec

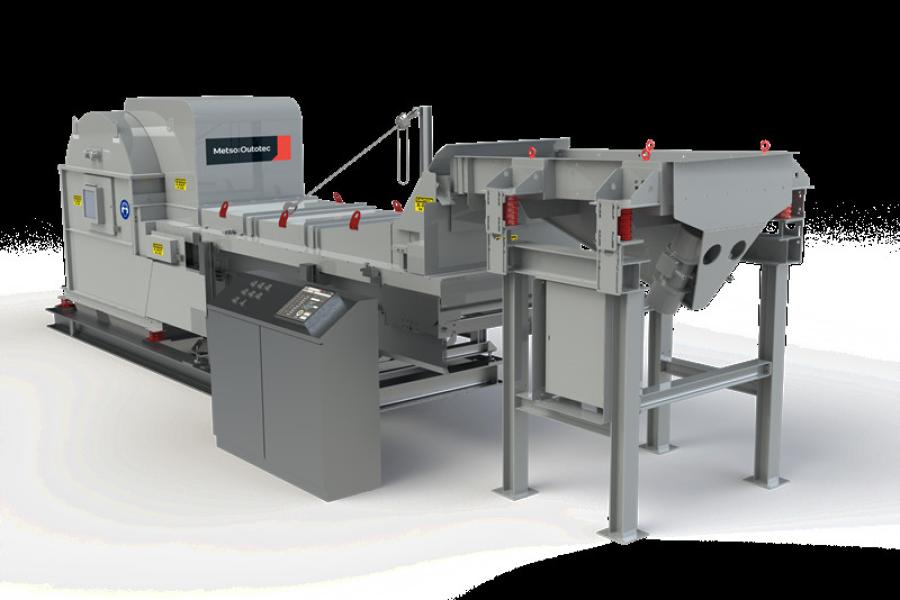

Metso Outotec and TOMRA Mining have agreed to continue the non-exclusive cooperation to supply particle ore sorting solutions for the mining and metallurgical industries.

The collaboration expands Metso Outotec's and TOMRA's capability to offer leading-edge solutions that help increase the overall value of ore deposits by reaching new levels of energy efficiency and productivity, decreasing costs and extending the life of mining operations.

"Separating ore from waste rock as early and as efficiently as possible is essential in minerals processing. The best result can be achieved by combining state-of-the-art crushing systems with advanced ore sorting. The combination of Metso Outotec's crushing know-how and TOMRA's particle ore sorting expertise is an excellent match, providing substantial benefits to our customers," said Guillaume Lambert, vice president, crushing at Metso Outotec.

TOMRA's sensor-based sorting has been a proven concept in minerals processing, recycling and the food industry for nearly 50 years. It can reduce specific energy consumption by 15 percent, as well as the amount of water used by three to four cubic meters per tonne of ore. This makes it an extremely cost-effective and sustainable solution that can benefit both mining operations and the environment, according to the companies.

"TOMRA, as an original equipment manufacturer, can add significant value to the process and engineering optimization of sensor-based sorting inclusive solutions when engaging with our customers within a cooperation agreement framework," said Mathilde Robben, key account manager at TOMRA Mining.

For more information about Metso Outotec, visit mogroup.com.

For more information about TOMRA Sorting, visit www.tomra.com/en/sorting/mining.

Aggregate Equipment

Aggregate Equipment Articles

Articles Sign up for Updates

Sign up for Updates Sell Your Machines

Sell Your Machines

Aggregate Equipment

Aggregate Equipment Aggregate Dealers

Aggregate Dealers Aggregate Articles

Aggregate Articles Sign up for Updates

Sign up for Updates Sell Your Machines

Sell Your Machines