Wed April 08, 2020

Esco

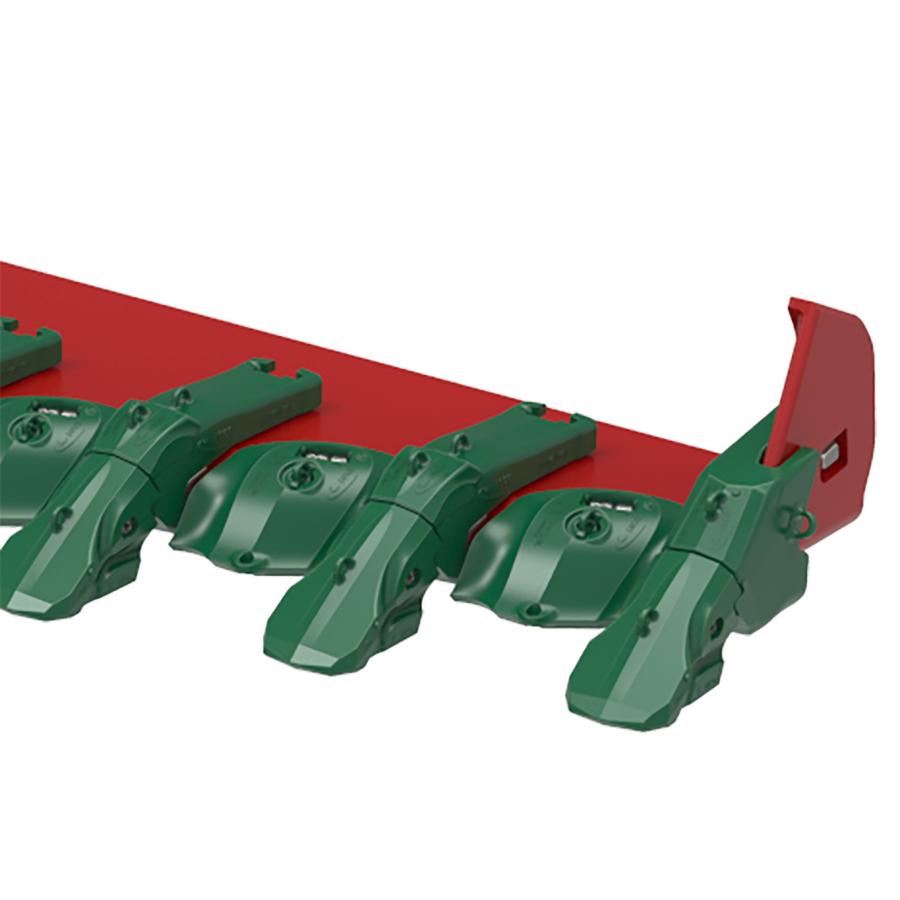

With more than 4,000 digging hours of testing and validation, ESCO's Nemisys Lip System for wheel loaders offers a distinct advantage for global mining operations, according to the manufacturer.

The Nemisys tooth system is a field-proven performer with installations on more than 500 machines worldwide. Initially developed for large mining shovels and hoes, the system is now configured for optimum performance on wheel loaders.

The Nemisys lip system features an integrated single-side lock for easier and faster removal to minimize machine downtime during maintenance cycles. The hammerless lock provides improved engagement with the nose to significantly reduce the chance of point loss and unplanned downtime.

Plate lip assemblies can be configured to meet customer requirements – available in 10 or 15-degree step spade versions. Adapter options are ESCO's T4 mechanically attached system or weld-on adapters. Both styles include a standard or super-duty wear cap.

There are three loader point options: general purpose that provides the best balance of penetration and weight; an abrasion/penetration style that provides excellent loading and long life in hard abrasive applications; and the ultimate abrasion point for maximum wear life in extreme abrasion.

The Nemisys components also can convert existing buckets to the premier ESCO system for exceptional performance and a lower cost of ownership over conventional lip systems, according to the manufacturer.

For more information, visit www.esco.weir.

This story also appears on Construction Equipment Guide.

Aggregate Equipment

Aggregate Equipment Articles

Articles Sign up for Updates

Sign up for Updates Sell Your Machines

Sell Your Machines

Aggregate Equipment

Aggregate Equipment Aggregate Dealers

Aggregate Dealers Aggregate Articles

Aggregate Articles Sign up for Updates

Sign up for Updates Sell Your Machines

Sell Your Machines